B4, Qingdao High-Tech Zone, No. 17 Songyuan Road, Qingdao.

+86 13864822549

Edge banding machine is a kind of woodworking machinery. It belongs to solid wood machinery.As the name suggests, the edge banding machine is used for edge banding. The traditional manual operation process is completed by highly automated machinery. Including conveying, gluing and pasting,...

Our ZX388 automatic edge banding machine has similar confirguration as ZX368 model. It is suitable for straight-line edge sealing and trimming of medium density fiberboard, blockboard, solid wood board, particleboard, polymer door board and plywood. It can cut off the edge sealing belt with double-sided gluing at one time, glue and compress the edge sealing, trim, chamfer, rough trimming, fine trimming, scraping, polishing and other functions.

Function introduction:

Pre milling: double milling cutters are used to modify the ripple marks, burrs or non vertical phenomena caused by cutting board saw / cutting saw, so as to achieve better edge sealing effect. It makes the edge banding strip fit more closely with the plate, and has better integrity and aesthetics.

Gluing and edge sealing: through the special structure, the double-sided gluing of edge sealing plate and edge sealing material is uniform to ensure more firm adhesion.

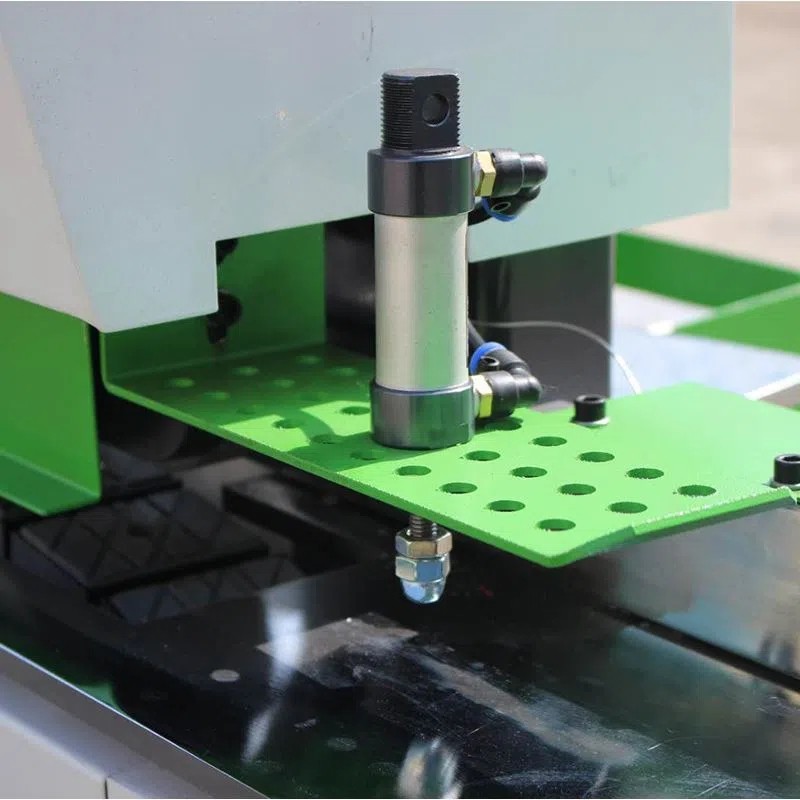

End trimming: through the precise linear guide rail movement, the profiling automatic tracking and high-frequency high-speed motor fast cutting structure are adopted to ensure that the cutting section is flat and smooth.

Fine trimming: automatic profiling tracking and high-frequency high-speed motor structure are adopted to ensure the flatness and smoothness of the upper and lower parts of the trimmed plate. It is used to repair the excess edge sealing materials above and below the processing plate edge sealing strip. The finishing knife is an R-shaped knife. It is mainly used for PVC and acrylic edge banding of panel furniture, and the edge banding with a thickness of more than 0.8mm is preferred.

Edge scraping: used to eliminate the ripple marks caused by the cutting process of trimming non-linear movement, so as to make the upper and lower parts of the plate more smooth and tidy.

Polishing: clean the processed plate with cotton polishing wheel, and make the edge sealing end face more smooth through polishing.

Grooving/Slotting: it is used for directly slotting the side plate and bottom plate of wardrobe to reduce the process of panel saw and make it more convenient and fast; It can also be used for slotting the aluminum edge of door panel.

Tech Parameter

Name | Edge banding machine |

Type | ZX388 |

Thickness of work piece | 10-55mm |

Height of edge banding belt | 10-70mm |

Thickness of edge sealing | 0.3-3.5mm |

Min length of work piece | 60mm |

Min width of work piece | 40mm |

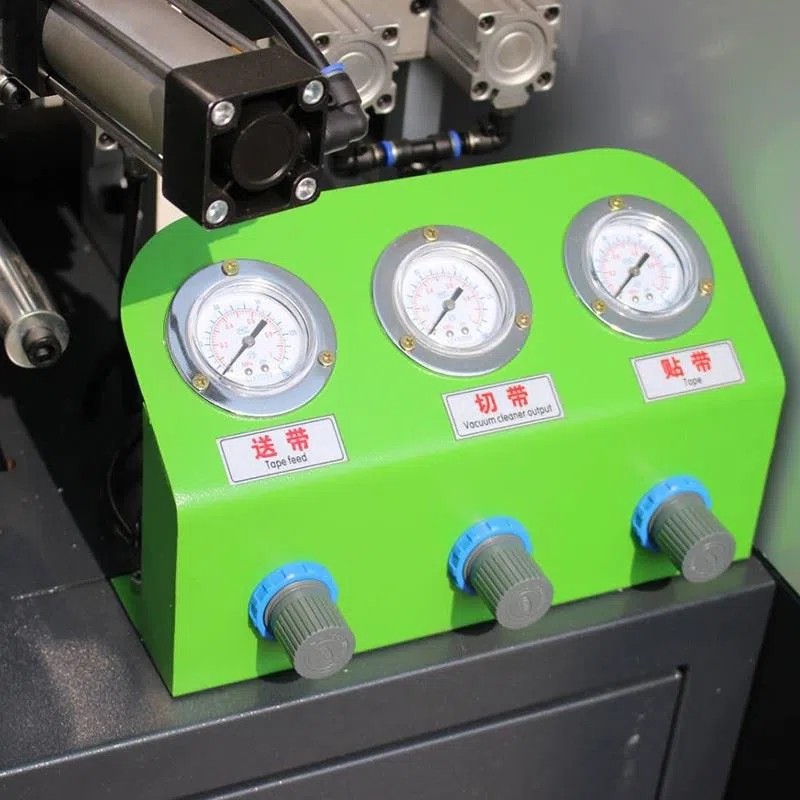

Air pressure | 0.6-0.8Mpa |

Feeding speed | 18m/min |

Board pre-heat power | 0.3kw |

Glue tank heating power | 1.8kw |

Glue tank transmission power | 0.55kw |

Conveyor motor power | 1.5kw |

End cutting motor power | 0.55kw*2/ 12000r/min /200HZ |

Rough trimming motor power | 0.75kw*2/ 18000r/min /300HZ |

Fine trimming motor power | 0.75kw*2/ 18000r/min /300HZ |

Polishing motor power | 0.18kw*2 |

Total power | 9.0kw |

Overall size | 4200*1000*1500mm |

Haosail with experienced management team, average working experience is around 15 years.Also Haosail with brand store in Maputo of Mozambique, Dubai and Singapore, every branch implements localization management, in order to serve customers more better.

Why to choose Haosail?

1. Compared to the factory which can only provide single product, we can offer you one-stop purchasing, provide whole set of equipment and turnkey solution for your garage.

2. Compared to normal trading company, we have abroad sales stores and professional after-sale team. You don't need to worry about our company strength, equipment installation and maintenance problems.

3. Compared to normal sales company, we have our LOGO on all of our equipment, Uniform color, if you want to start your own business or act as a product agent, we are the best solution for your investment.

How about your service?

1. Consultation before, during, and after sales;

2. Project planning and design;

3. Provide local service for installation and operator training in Mozambique and Dubai. For other countries and areas, we will provide instruction documents and on line assistance.

What about your leading time?

We have brand shops in Mozambique, Singapore and Dubai. After you place an order, we will finish production in 30 days. For big quantity, we can talk further.

What about the transportation and delivery date?

Our machine needs to be loaded into container and ship by sea, it takes about 25-40 days. It also depends on which country and port you are.

Qingdao Haosail Machinery Co., Ltd., founded in 2008, is an integrated enterprise specilizing in the design, production, sales, and service of auto maintenance equipment. We not only sell products, but also provide project package services, including project layout design, one-stop purchasing, installation and training, have established cooperative relations with many demestic and foreign customers.

We have operations and experience centers in Africa, the Middle East, and Singapore that provide localized services.

Haosail's products are passed Third Party Inspection -JINGRUI TEST CENTER's quality management, which can achieve quality traceability and make customers feel at ease.

Our philosophy: Looking forward to the establishment of cooperation with customers, including product sales agent, project contract supporting. Haosail, your auto-repair partner from zero to success.