May 29, 2025

May 27, 2025

Apr 14, 2025

Apr 07, 2025

B4, Qingdao High-Tech Zone, No. 17 Songyuan Road, Qingdao.

+86 13864822549

Air Compressor Types:

Based on working principles, air compressors can be divided into volumetric and dynamic types. Volumetric types can be further divided into reciprocating and rotary types. Reciprocating types include piston and diaphragm types; rotary types include twin-rotor and single-rotor, which are further classified into sliding vane, liquid ring, worm gear, screw, and Roots types. Dynamic types can be categorized into centrifugal, axial flow, and jet pumps. Screw and piston air compressors are the two most popular models in the air compressor market.

Piston air compressors have the advantages of simple structure, long service life, and the ability to achieve high capacity and high-pressure output at a low cost. Their disadvantages include large vibration, high noise, and intermittent exhaust, which results in pulsating output and the need for an air receiver.

Screw compressors have the advantages of stable pressure, low noise, high level of automation, easy maintenance, and are suitable for large exhaust volume applications. Their disadvantage is the high purchase cost.

Classification of piston air compressors:

1. By power source: Electric motor, diesel engine

2. By drive method: Direct coupling, belt drive

3. By lubrication method: Oil-lubricated, oil-free (silent oil-free)

4. By cylinder arrangement: Vertical, horizontal, V-type, W-type

Applications of air compressors:

- Pressurization: Metal casting, forging, etc.;

- Chemical reactions: Chemical reactions in chemical plants, oxygen production, nitrogen production, etc.;

- Driving equipment: Air guns, nail guns, robotic arms, pneumatic drills, pneumatic picks, etc.; 0.6-1.5MPa

- Surface coating: Sandblasting of metal surfaces, surface painting, etc.;

- Dust transportation: Coal powder transportation in power plants and smelters, dust transportation in cement plants, etc.;

- Blowing and sweeping: Cleaning of power plant pipes, blowing of iron shavings and dust in smelters and machine shops, cleaning of workbenches, etc.;

- Ventilation: Ventilation in tunnels and underground mines;

- Blowing and inflating: Tire inflation, blow molding, pipe blowing, bottle blowing, food filling, etc.;

- Control instruments: Control of machining centers, machine tools, printing machinery, auxiliary equipment in power plants, train braking systems, railway track switching devices, opening and closing of vehicle doors and windows, control valves, instrument power 0.2-1.0MPa.

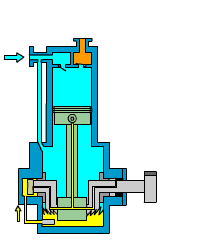

Piston Air Compressor Working Principle: The electric motor drives the crankshaft to rotate through a belt drive (in direct-coupled machines, the motor directly drives the crankshaft), and the connecting rod moves the piston in a reciprocating motion. This causes the space formed by the cylinder, piston, and valve assembly to change periodically, achieving the purpose of compressing air. The compressed air then passes through the exhaust pipe and a check valve into the air receiver.

The air compressor is equipped with a pressure switch that automatically cuts off power when the pressure in the air receiver reaches the rated exhaust pressure. When the pressure in the air receiver drops by 0.2-0.3MPa, the pressure switch closes, reconnecting the power supply and allowing the air compressor to resume operation. This maintains the air pressure inside the air receiver within a certain range.

To better serve our international customers, we have established operation and experience centers inKenya, Mozambique, Zimbabwe, Tanzania, Egypt, Dubai, Singapore.And our stores in Ghana, Zambia, Uganda, Algeria, and South Africa are also being prepared.

These centers provide localized services, ensuring that our customers receive the support they need, regardless of their location.

Quality is at the core of everything we do at Haosail. Our products have passed the third-party inspection by Jingrui Test Center's quality management system, ensuring that our products meet the highest standards of quality and reliability.

We look forward to establishing long-term cooperative relationships with our customers, offering not only product sales but also project contract support. Haosail is more than just a supplier; we are your partner from the initial stages of your project to its successful completion.